October 8, 2015

Life is full of trade-offs. Do I buy the quality beer or go for volume? Should I take the high paid job or the job with lots of holidays? The answer to the second question may dictate the answer to the first!

Harvest weed seed control (HWSC) is full of trade-offs. Some options are excellent but expensive. Others are cheap but require compromise.

For example, narrow windrow burning appears cheap, but has a high hidden cost of nutrient removal and requires a lot of labour to burn the windrows. The Harrington Seed Destructor is the dead opposite.

In this AHRI insight we quantify the cost of six HWSC tools. One of the tools can cost as little as 10c/ha while another can cost as much as $60/ha. The cheaper tool may seem the obvious choice, but it is not quite that straight forward.

There are currently six HWSC tools being used by Australian grain growers. All remove weed seeds at harvest but they come at different capital cost, running cost and cost of nutrient removal. To compare these tools we must first consider the running cost, and then add the nutrient cost to get a realistic comparison.

There are three categories of HWSC

Running cost

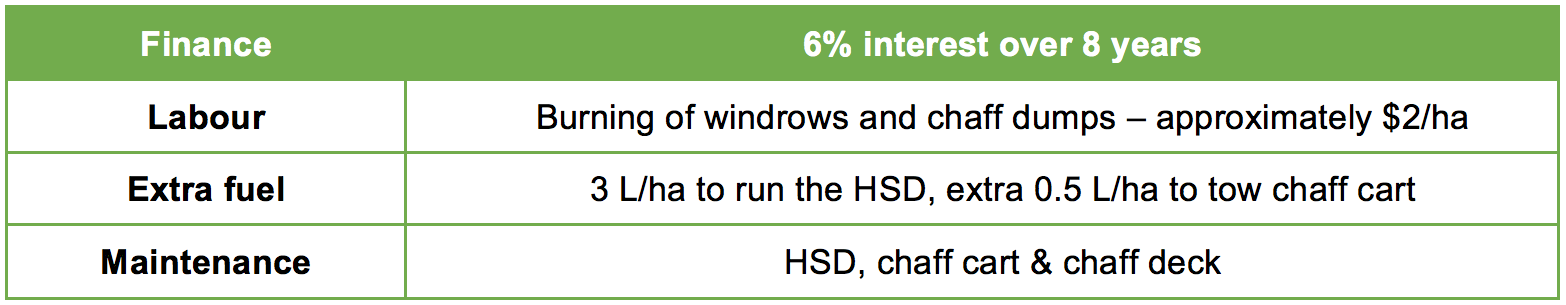

The running cost of the various tools was calculated assuming that the harvester covers 2000 hectares each year. A bigger area will reduce the finance cost per hectare and vice versa. The running costs include:

The capital cost and the running cost of these tools in the table below are indicative only and based on current pricings.

Once we know the running cost, we then need to add the cost of nutrient removal per tonne of grain harvested and multiply by yield. To do this we assume that 50% of nutrients in the residue is returned to the soil if it was to be retained. This is a rubbery figure and can be adjusted. The biggest nutrient costs are Potassium (K) and Nitrogen (N). Some growers have soil with very high K levels and wish to ignore this cost. There are other benefits of full residue retention that we are aware of but haven’t quantified in these calculations.

Chaff line

The chaff line technique is clearly the cheapest. Chaff lining involves making a simple chute to divert the chaff only fraction (off the sieves) into a narrow windrow which is left to rot/mulch while the straw is chopped and spread. This system is in the early days of development and we are still learning about the benefits and drawbacks of leaving strips of concentrated chaff containing potentially very high numbers of weed seeds. Observations of growers using this system suggests that low numbers of weeds germinate in the chaff line. There are unknowns, but it is certainly worth a try in a paddock or two. Low cost, low tech, low labour. Check out this past edition of AHRI insight for more info.

Chaff deck

The chaff deck is also low cost and is well suited to growers with controlled traffic farming systems. Once again there are concerns that the weed seeds are left in the paddock rather than being destroyed. Anecdotally, growers who have been using this system for many years comment that their permanent tramlines are getting cleaner the longer that they use this system.

Chaff cart

The chaff cart is a medium cost option with low levels of nutrient removal. For mixed farmers this option has the benefit of allowing the grazing the chaff dumps in the field or in a feedlot. Frequently the direct grazing of chaff dumps means there is no need to supplementary feed sheep or to subsequently burn the dumps as remaining residue can be seeded through. Check out these WeedSmart webinars with Andrew Boultbee and Mark Wandel.

Narrow windrow burning is best suited to lower rainfall environments with high Potassium soils.

The bale direct system is profitable where a market for straw bales exists close to the farm.

The Harrington Seed Destructor (HSD) quoted in the table represents the currently available tow-behind unit. The capital and running cost of the HSD are high in comparison to other systems but there is no nutrient removal cost.

Clearly, expensive capital items such as the HSD are best suited to bigger farms that can average out the capital cost over a larger area of cropping.

Summary

The integrated destructor mill is very exciting. Early indications are very good and when it comes to market it is likely to have a big impact. Watch this space (hopefully not for too much longer!).

The chaff cart has a big future for mixed farmers, they are good for the sheep and good for the crop.

The chaff deck and chaff line are good low cost options for controlled traffic farmers, but the weeds are still in the paddock. We need to continue to research these options.

Bale Direct is profitable in the odd rare situation where a big market for bales exists.

No compromise

We are looking for the ultimate system with no trade-off. A system that is cheap, reliable, and convenient. For mixed farmers, the chaff cart may well be it. For the crop dominant farmers the integrated destructor mill will hopefully be the answer. In other words, quality beer with lots of holidays!

P.S. We’re giving RIM a break. New RIM runs are back in November! (Here are the ones we’ve done so far).

P.P.S. Are you interested in staying up to date with weeds, pests & disease? If the answer is yes, the inaugural Crop Protection Forum (hosted by AHRI and CCDM at UWA) is an opportunity to learn about resistance and how to blunt its evolution. Find out more and register here.

P.P.P.S. In exciting news, Stephen Powles has a new online course brought to you by WeedSmart’s Diversity Era. Starts November 16! For more details and to get your free account (it’s easy), click here.

Follow the links below for further info:

- Past AHRI insight: Spoiled Rotten

- WeedSmart webinars: Win the war against weeds

- AHRI & CCDM Crop Protection Forum

- Past RIM runs

- Diversity Era online course: Herbicide Resistance 101 with Stephen Powles

Posted in: Uncategorised